Before the 1990s, swirl wells and horizontal sedimentation tanks were widely used in steel and metallurgical industries to treat turbid circulating water. There were many problems, such as large area occupied by the system, low treatment efficiency and low energy utilization. In combination with the application of chemical deoiler and high-efficiency clarifier products developed by our company in the industry, we take the lead in developing and introducing high-efficiency turbid water purifier with high cost performance ratio and its matching high-efficiency hydraulic mixing device in the industry, forming a new short-process treatment process, which greatly improves the efficiency of water treatment, while resolving the numerous existing conventional devices. Problem. Great success has been achieved in iron and steel and metallurgical industry since 2006. Up to now, high-efficiency turbid water purifier and treatment process are still the preferred technology and important means of water treatment in relevant industries.

High efficiency turbid water purifier is a sewage treatment equipment integrating reaction, precipitation and separation. It is a renewal product of conventional mechanical stirring clarifier, advection sedimentation tank and chemical deoiler. It has many national patents. It is mainly composed of mixing reactor, mixer, sludge reflux device, inclined pipe, mud bucket and other components, which are divided into open and closed types. The pressure of the outlet water of the sealed equipment can directly enter the next user, which reduces the number of equipment while shortening the processing flow, improves the matching degree of the equipment system, reduces the probability of system failure, and improves the production efficiency.

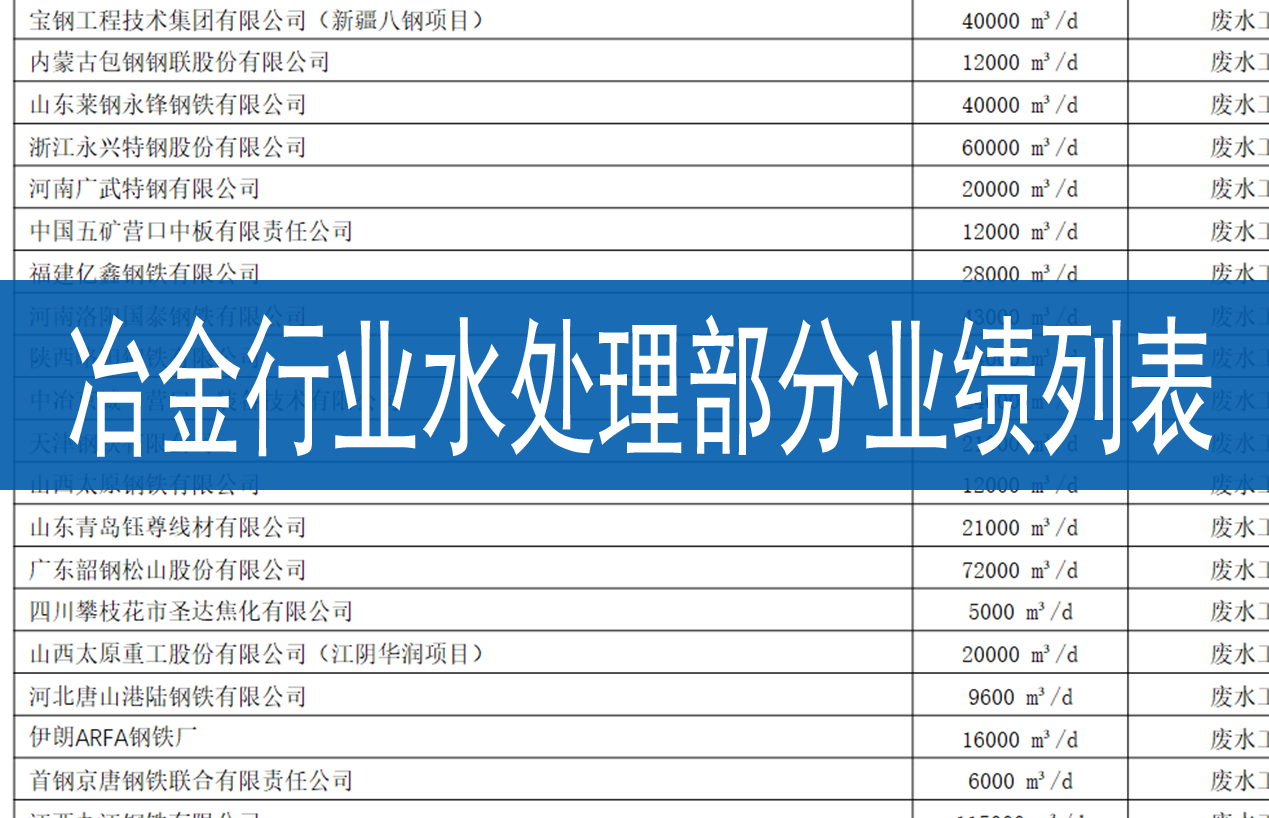

High efficiency turbid water purifier can be widely used in the treatment of turbid water in steel and metallurgical industry, the treatment of dust-removing wastewater in converter and blast furnace, the washing and drainage of ore yard, the treatment of initial rainwater, the treatment of wastewater in machine-processing industry, the treatment of wastewater in stone processing industry, the treatment of sludge filtrate and river treatment, etc. At present, our company has hundreds of equipments serving large-scale iron and steel enterprises all over the country. Hundreds of projects in metallurgical and other industries.

The core of high-efficiency turbid water purifier is our patented technology - non-power hydraulic cycle purification technology. The unique swirl water distribution device, high efficiency sedimentation zone design and no external power hydraulic internal circulation system make it possible to provide 25-40m < sup > 3 m < sup > 2 h high hydraulic load while satisfying the effluent quality. The high efficiency sedimentation zone, suspended mud sand layer and high efficiency co-pipe device make the equipment have multi-stage purification function and realize high quality effluent. Compared with traditional process equipment, it has the following advantages that other conventional equipment can not replace:

―― The comprehensive one-off investment and operation cost are lower than those of traditional technology and equipment, and the equipment has strong adaptability and anti-shock load ability, and the equipment runs stably.

―― Internal parts without mechanical transmission and maintenance, saving power consumption, reducing the workload of operation and maintenance, and reducing maintenance costs用。

―― Adding high concentration hydraulic circulation system to improve mixing and reaction effect.

―― The internal circulation system utilizes sludge return from the sludge bucket to maximize the utilization rate of chemical agents, and the mixing reaction with sewage is more efficient.

―― Hydraulic internal circulation drives sludge internal reflux, increases flocculation carrier capacity, enhances flocculation, flocculation effect and alum particle size, enhances sludge water separation effect, and greatly improves sedimentation hydraulic load.

―― The large volume and independent cone bucket sludge collecting and the same way sludge discharging system are adopted to avoid dead angle and short flow, and the sludge discharging is cleaner and more thorough.

―― The water content of slurry in bucket is about 95%~97%. Compared with the slurry in traditional sedimentation tank, it can reduce the amount of water carried out outside the slurry discharge, reduce the scale and operation cycle of slurry conveying equipment, and realize energy saving and consumption reduction.

―― Equipment serialization and standardized production (diameter 3m/3.6m/4m/non-standard type); complete supply, overall transportation and installation; no on-site splicing workload; high construction efficiency, greatly shorten the construction period compared with conventional technology.

―― Internal multi-stage series treatment makes the effluent quality higher without back-end series filter.

―― It occupies only 1/4-1/3 of the area of traditional chemical deoilers and high-efficiency clarifiers, thus saving land resources.

《Code for Design of Industrial Circulating Cooling Water Treatment》GB 50050-2007

《Discharge Standard of Water Pollutants in Iron and Steel Industry》GBT 13456-2012

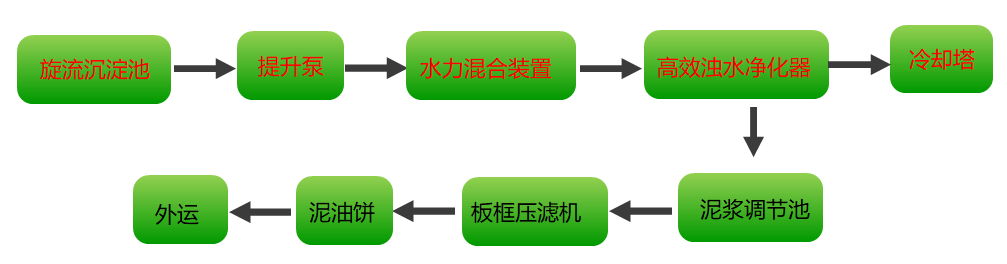

Wastewater is elevated by the intake pump group into the hydraulic mixing device, which is used for hydraulic circulation and eddy current mixing, so that PAC liquid and sewage can be thoroughly and fully mixed once. The sewage from the primary mixing reaction is fed into the secondary reaction chamber of the hydraulic mixing device by using the built-in swirl water distribution device. Through the built-in hydraulic guide and high efficiency reactor, the PAM liquid and sewage are completely and fully mixed. At the same time, the large granular sludge in the sewage can settle rapidly to the sludge bucket where the bottom water flow is stationary, thus reducing the load of subsequent treatment. Wastewater from secondary reaction is evenly distributed to each high-efficiency multi-functional wastewater treatment unit through the outlet pipeline of the hydraulic mixing device. Due to the unique mixing and reaction mechanism inside the hydraulic mixing device, PAC and PAM liquid are fully mixed with water. Once again, through the hydraulic cycle, eddy current mixing and sludge reflux built in the high-efficiency turbid water purifier, the sludge concentration is continuously increased. With the aid of the bridge-erecting function of macromolecule reagent adsorption, the oil and particulate matter are rapidly separated, the agglomeration and flocculation particles are gradually enlarged and rapidly coalesced, forming the large particles in the best reaction state, and entering the bottom sludge collecting bucket where the water flow is still, and settling rapidly. Fine particles that fail to settle in time are intercepted by the water flow into the suspended sludge layer and further settled in the inclined pipe settling area. Under the action of the inclined pipe, the fine particles gradually coalesce and slide into the settling chamber. The sludge settled in the sludge collecting hopper of the hydraulic mixing device and the bottom sludge collecting hopper of the high-efficiency multi-functional wastewater treatment device can be automatically discharged (or manually discharged) through the matching electrical control box, and then be discharged into the slurry pond for subsequent treatment. The clarified water enters the catchment system and flows out of the equipment.

1.Short Process Flow of High Efficiency Turbidity Water Purifier

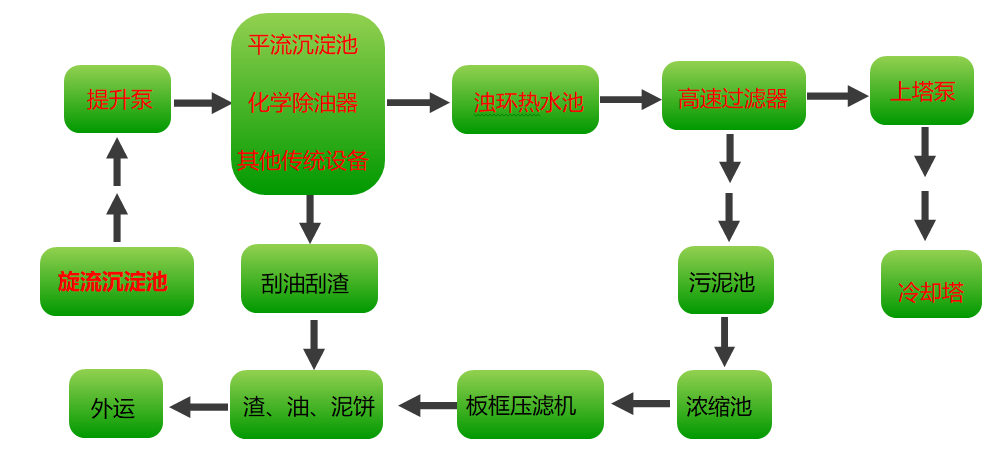

2.Traditional process flow: advection sedimentation tank/chemical deoiler/other traditional equipment