Green Heng Science and Technology-The Anaerobic Project of Xingxin Paper Industry in Guigang, Guangxi has passed the acceptance of the project

2018-11-08

Survey

On October 29, 2018, an acceptance group was formed by the general manager of Xingxin Paper Industry, the director of the production plant and the leaders and experts of the relevant environmental protection departments. The acceptance group completed the acceptance of the anaerobic wastewater treatment project of Xingxin Paper Industry in Guigang, which was constructed by Beijing Green Heng Science and Technology Co., Ltd. The acceptance group and experts inspected the operation of the wastewater treatment equipment, the effluent effect and the quality of the project on the spot, Relevant technical information, check the acceptance monitoring report, confirm that the effluent indicators meet the requirements of national discharge standards, agree that the performance test and engineering quality of the project meet the requirements of completion acceptance, and the project passes through with higher evaluation acceptance.

Construction background

Guigang Xingxin Paper Co., Ltd. is one of the largest recycled paper enterprises in Guangxi. It uses waste paper as raw material to produce corrugated paper with an annual output of about 150,000 tons. With the increasingly stringent environmental protection requirements, the original sewage treatment process and facilities can not meet the environmental protection requirements. Therefore, the owners consider the construction of an efficient anaerobic treatment system. The LOC external circulation high efficiency anaerobic reactor independently developed by Luheng Company is an anaerobic reactor specially designed for high concentration wastewater produced in papermaking, chemical industry and food industry. It has the characteristics of high COD removal efficiency, stable performance, small occupation area and strong impact load resistance. After many technical exchanges and communication with the owners, the technical scheme provided by Lvheng has been fully recognized by the owners. Eventually, Lvheng Technology is entrusted with the overall package of process and equipment for the anaerobic system and pre-precipitation system of the wastewater station, and is responsible for the design of process system, the processing, production, installation and commissioning of process equipment and auxiliary equipment until the effluent reaches the standard stably.

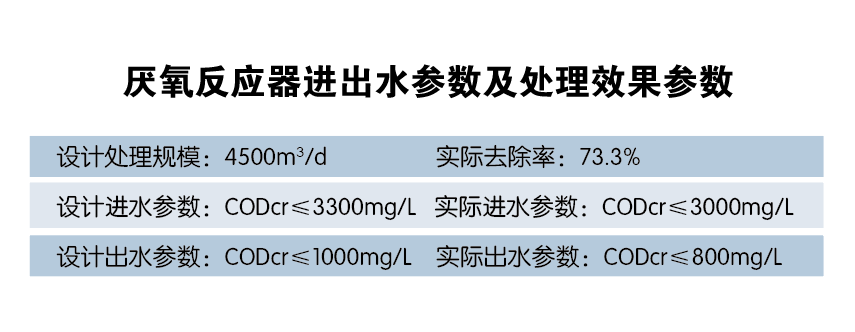

Treatment effect

The project started construction in May, 2018. After more than five months of construction and system debugging, the project has been running steadily and the effluent quality has reached the discharge standard of paper industry.

Built meaning

The completion and operation of the project fundamentally solved the problem of stable discharge of paper-making wastewater from Xingxin Paper Industry and effectively improved the ecological environment. At the same time, on the basis of the original treatment process, the additional pre-precipitation system reduced the original chemical dosage of the owner. The operation of the anaerobic system provided stable water quality and quantity for the subsequent aerobic treatment and ensured the whole sewage area. The stable operation and standard of the management system. Biogas and granular sludge produced by anaerobic system have certain economic value. The construction of the project not only saves the cost of sewage treatment operation for the owners, but also brings remarkable social and economic benefits.

Brief Introduction of Technology-LOC External Circulation Anaerobic Reactor of Greenhouse Technology

LOC anaerobic reactor is developed on the basis of traditional UASB reactor and EGSB anaerobic reactor. The core of LOC anaerobic reactor is based on a specially designed water distribution and three-phase separation module, which realizes the highly turbulent state of wastewater in the reactor, promotes the full contact between wastewater and anaerobic microorganisms, improves the efficiency of anaerobic mass transfer reaction, and effectively intercepts biological carriers to ensure that the reactor is always in the interior. In a state of high efficiency and benign circulation, the pollutants in water are degraded by a large margin, and the by-product biogas can be used as energy.

Technical characteristics

1.Vertical structure, covering an area of provincial, generally 12-20 meters in height;

2. High organic load, short hydraulic retention time, maximum volume load up to 20 kg COD/(m.d);

3. Low upwelling velocity and energy saving (the upwelling velocity should be controlled at 2-4 m/h without excessive reflux);

4. It has strong resistance to shock load and toxicity, and is widely used in the treatment of industrial wastewater.

5. The special design of three-phase separator can fully promote the growth of microorganisms and increase the biogas yield (gas yield can reach 0.4 m/kg COD).

6. There are no running parts, no maintenance and long service life.